Oct

31

2009

Late in every afternoon, there is a 7:30pm Happy Hour on the Single Side-Band Radio (SSB) and sailors get together and talk about things. There was a big discussion about the weather because a storm was supposedly blowing into our path. We had some repairs to make to the head (on-board toilet), and no one could bear the thought of repairing it while sloshing around in big seas. So, we changed our course and headed in towards the shore to a little anchorage called Bahia de San Quintan.

The Cruising Guide described this as a “rolly” anchorage. We found what we thought was a nice place to anchor, and we set the hook for the boat. There were a few others around us, but several other boats were moored over on the other side of the bay.

Once on the hook, part of the crew finished the head repairs, one crew completed miscellanous tasks around the boat, and I cooked a nice dinner (pesto chicken burritos with onions, garlic, tomatoes and cheese), cracked a bottle of wine, and sat around the dining table together.

Afterwards, we had a little dessert and some after dinner drinks, and then headed to bed.

A couple of times during the night, I got up to check the status to the boat (as did the others). The wind had shifted and we were getting these strange rolling waves during the night.

Around 4:30am, I heard the roar of a wave . . . which proceeded in crashing right onto the boat and into the cockpit. I was thrown flying from my bunk and onto the cabin sole. (Not so nice wake-up call). We all got up to survey any damage (there was none) and make a plan for the day . . . and, we decided that rather than take another hour to reset the anchor somewhere else in the bay that two would volunteer to take the first watch, and we would move forward. I volunteered, and we were off!

All-in-all, about 60 boats moored in Bahia de San Quintan. I hope we were the only ones with THAT problem.

Oct

12

2009

The preparations for the race boat consumed another weekend, and after all of the work was finished (for the day), I had less than two hours of sunlight to seal my own boat from the rain coming tonight.

The preparations for the race boat consumed another weekend, and after all of the work was finished (for the day), I had less than two hours of sunlight to seal my own boat from the rain coming tonight.

I know, I know–I should have done this last month, or even the month before, but I have been busy . . . For the last two years, actually.

Anyways, the boat is sealed for the rain. The work is ugly, but overkill,and should accomplish the one goal of keeping me dry.

The storm tonight is expected to be brutal. Gusts of wind up to 65 knots in the central bay.

UPDATE: I beat the rains by 4 hours on this. Too close for comfort, but at least it is done!

Aug

22

2008

One of the items on the long list of todos is to repair the Homestrand Model 206 Alcohol 2-burner stove on the Ericson 29.

After a little productive searching on the Internet, I found a nice company in Brewerton, NY that sells original repair kits. So, I called them and ordered one–or, two rather (one for each burner). They arrived today, in perfect condition with a hand-written note, printed instructions, and a postcard of their boat yard. So cool!

If you need Homestrand Model 206 (or 209 or other) Alcohol Stove parts, they have them:

ESS-Kay Yards (on the Erie Canal)

Brewerton, NY

By Phone: 315-676-2711

On the Internet: www.ess-kayyards.com

Note: You can order things online–they have a shopping cart and payment processing, but at the time of this writing, it does not use SSL technology–so, your credit card and info goes all over the Internet unencrypted. They said they are working on it.

I’ll post a tutorial when I am finished rebuilding the stove.

Aug

18

2008

After crawling around below the cockpit sole, there was absolutely no evidence of a collision. Furthermore, there is another Ericson 29 on the hard nearby with the same full-length cracking along the top of the transom.

The material that has actually split is a dark gray with some un-catalyzed fiberglass flakes in it. Underneath, there is plenty of glass holding things together on the inside edge, but my guess is that the outer edge was stuffed with filler. This seam across the transom is the only place where the hull-to-deck joint is not bolted together.

I am going to clamp the area together and fill the whole thing with epoxy–allow it to cure and basically glue the whole thing together (there is no worry about the structural integrity here–the transom is sound).

Aug

18

2008

Stripped and re-finished hatch board

I have completed the first board, and I love how it looks.

These boards get quite a bit of use, and as a result, I wanted to use Teak Oil, rather than varnish. In my mind, it is easier to keep them oiled than it would be to keep them varnished. With the boards getting used dozens of times a day, the chances are pretty great that varnish would get chipped or marred. (I am sure my opinions will change after a few seasons of this.)

The board cleaned up really well with just water and a stiff, plastic bristle brush. I used the Interlux Teak Restorer additionally to get some of the stains out of the wood. By the time it was dry, the wood was white.

As per the directions on the Interlux Teak Oil, I brushed on a coat after the board was dry, waited until it was dry to touch, and applied a second coat. I let that dry for the remainder of the day, and honestly, it needed more. That wood was THIRSTY!

The interior side is perfect. The exterior side still has a really pronounced grain that is a bit course to the touch. I am going to hand sand it with 80-grit, then 150-grit sand paper, wipe away the dust, and then re-apply the Interlux Teak Oil.

Aug

17

2008

Hatch boards before they were stripped and refinished

This is the BEFORE picture of the Cabin Hatch Boards on the Ericson 29. They are teak, well-weathered and ready for a refinishing.

I chose Interlux Teak Restorer, and Interlux Teak Oil. The grain has become a bit pronounced, so I may be doing a bit of sanding later to return them to their previous smoothness.

I’ll post pictures as I go.

Aug

14

2008

Another guy from the marina (who has an Ericson 27) came over today and we looked at the transom together. I needed another set of eyes to verify what I was seeing.

The crack across the transom goes nearly all the way across–right along the top. But, the crack is not in the fiberglass: it appears to be some other material that was used along the top of the transom. And, whatever that material was, it appears to have sheared from the stress.

The backstay is attached, of course, and definitely holding the transom in-place. I am not worried about it coming apart. The next step is to determine where, when, and why this other material was added. I will be looking for evidence of a collision . . . and this to be part of the repair process.

Tomorrow, it looks like I will be crawling around below decks.

Aug

13

2008

Crack along the transom of an Ericson 29

Upon most accounts, the Ericson 29 is a stoutly-built boat that could handle the Blue-water conditions of cruising. It will be small, and have a maximum hull-speed of 6.7 knots/hr, but it will be manageable.

The smaller boat might actually be more forgiving in many places. There are not as many things to break, a smaller boat is easier to maneuver, and has a shorter mast. It is less helm on the tiller, and the keel is shorter–so, I can get in a little closer to shore.

A longer, heavier boat wouldn’t get tossed around as much in heavier seas, and the extra waterline would mean faster days. But, the cost of the boat is more, as well as every other thing.

And, I already own the Ericson 29.

There is this nasty little split along the seam of the transom, however (see picture). It appears as if the top portion of fiberglass did not bond properly to the actual transom. If it is repairable and does not pose any danger to the structure of the boat, perhaps it is not a big deal.

I am going to have to hire a marine surveyor to tell me if this boat is worth preparing for the voyage, or not . . . .

Aug

02

2008

Although there may be fiberglass, or wood, or aluminum, or steel, it really FEELS as if a boat were held together with rope–or, lines. The sails are attached, held up, and held down by rope (wire rope, polyester rope, cotton rope, etc.). One of the vital skills of seamanship is the ability to work with rope.

Fortunately, I grew up with ropes. In Boy Scouts, we learned knots, lashing, and splicing–all with single braid rope. Now, as ropes are more important than pitching my tent, the ropes have consequently become more complex–and, more specialized.

First Splice

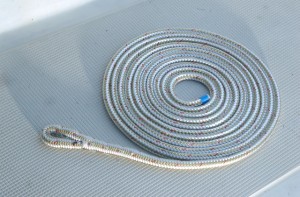

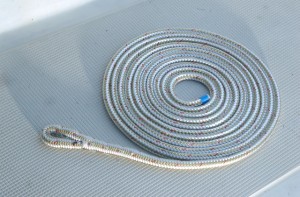

New dock line eyesplice in double-braid rope

It may sound like a martial arts move, but it really marks my first attempt at splicing a complex rope. I started with a useful splice: the eye splice.

This is going to be a bow-painter for the Lido-14, but I put a nice little eye splice in one end of a 20-foot section of double-braid line.

Tools Required

- 20-foot section of rope

- tubular fid and pusher set (I purchased the Samson kit)

- waxed thread

- whipping needle

Overall, I am happy with the result–although I would prefer less bunching of in the eyelet. I needed to pull the ends a bit tighter before I pulled the core back inside the cover.

In the next month, I will be replacing ALL of the lines, halyards, and sheets on the boat (with the exception of the lifelines–which I will be removing the plastic coating and assessing).

Jun

25

2008

Last weekend, the Cal Sailing Club hosted an intensive sailing workshop. As a result, there were more than a few casualties to the fleet of dinghys, and I swung by the club to help repair them last night.

The club has 5 Laser Bahia’s with a tiny Gennaker sail, a roller furling jib, and little square-top main sail (with reefing points). They are cute little boats, pretty fast, and really popular.

I spent a couple of hours last night swapping out shackles, fitting cotter pins, and taping sharp things (that could catch wetsuits, cut hands, etc.). Some of the other volunteers were working on different portions of the same boats. Towards the end of the evening, we replaced two of the repaired rudders, and the bulk of the mini-fleet of Bahias were back into operation.

This was excellent fun–almost therapeutic. Working on something, fixing something that was broken, and improving on designs with new ideas. And, then to have the product of your labors be seaworthy afterwards.

Great fun.

The preparations for the race boat consumed another weekend, and after all of the work was finished (for the day), I had less than two hours of sunlight to seal my own boat from the rain coming tonight.

The preparations for the race boat consumed another weekend, and after all of the work was finished (for the day), I had less than two hours of sunlight to seal my own boat from the rain coming tonight.